Aircraft Fuel System Components - The storage space in the wing must be properly sealed to prevent rivets, bolts, nuts, fuel lines and hose to leak. This type of fuel tank must be capable of bending under aerodynamic stress, and to withstand expansion or contraction under ambient temperature changes.

The seal must support this through the operating temperature range as well as flight envelope. As North America's largest internet-based platform for aviation parts, we carry an extensive range of fuel system parts for sale for aircraft of all types.

Aircraft Fuel System Components

Whether you need one fuel system component, or many fuel parts to get the job done, we've got used airplane parts in stock for brands such as: Fuel pump systems are the ones used in more complex aircraft with low-wing designs, and they are more suitable when using integral tanks.

What Aircraft Models Do You Sell Aviation Parts For?

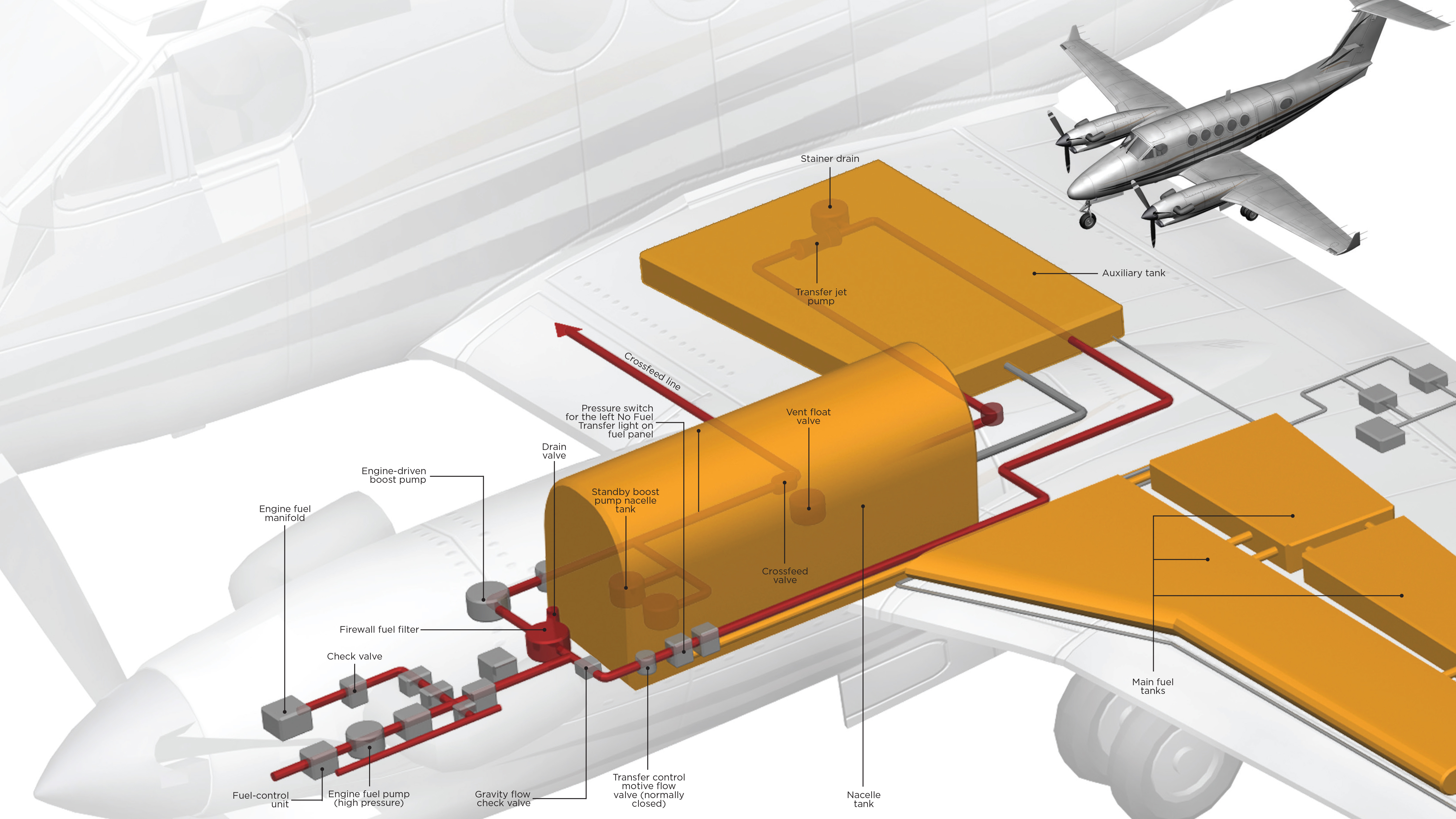

Yet, the other two types of tanks can also be used with a fuel pump system. All tanks are vented to the atmosphere, no matter the type. This is done so that ambient atmospheric pressure is maintained in the tank at all times to help prevent airlocks in the system which could occur if a vacuum was present in the tank.

After leaving the fuel tank, and before reaching the carburetor or injector, the fuel passes through a fuel strainer to get rid of any moisture in the system. These pollutants are heavier as fuel for aircraft so they settle in sumps in the bottom of a strainer.

Depending on fuel type and location, the fuel pump may include a drain pipe or outlet. Incidentally, has it ever occurred to you that when you drain fuel out of the gascolator to check for water, you are only checking the tank that the selector is set on?

If you want to check any other tank, you must change the selector setting and drain some more fuel. Right? I'm sure that, as a serious builder, you realize that we have only touched on the more important basic essentials for a fuel pump system, and that your own installation has to be made to suit your airplane - engine and fuel metering device (

Tank Ventilation

fuel injector or carburetor, that is) - and the kind of components you intend to install. If you need to return any parts from BAS, or if you'd like to request a replacement, you can do so within 90 days of the purchase date with no penalty.

However, we do not accept returns on any parts marked CORE, fuselages, or any other aviation part stating "no returns accepted." We will pay the return shipping costs if the return results from an error on our end, such as an incorrect or defective item.

Low-wing airplanes with tanks installed in their wings need pumps to transport the fuel from the tanks to the carburetor or injectors. A system dependent for pumps feeding the engines needs a minimum amount of redundant power achieved by using two fuel pumps, one driven by the main engine and one electrically driven.

The electric auxiliary fuel pump operates from an electrical switch inside the cockpit. Back-Up Pump Options A back-up by any other name may be an auxiliary pump, boost pump, electric pump or even a wobble pump.

Fuel Strainers And Sumps

They all serve the same purpose-that of helping the engine driven pump or, in extreme cases, taking over its function completely. As you know now, the engine fuel system of an aircraft is simpler than many people imagine, especially when it comes to light aircraft with a single engine.

Obviously, the bigger the airplane the more necessary fuel pumps become to make sure the flow is steady as required for proper operation. Some details about this part: Part Number: S3300-1 For Spares Order: S3594-3 Removed from 28 volt system

If you need additional pictures or have any questions, please let us know. 90-Day Money Back Guarantee: Guaranteed to work and pass your inspection... Some details about this part: Part Number: SA82 Alternative Part Number: S2020-2

Sold as a set of 5 If you need additional pictures or have any questions, please let us know. 90-Day Money Back Guarantee: Guaranteed to work and pass your inspection or... Since these fuel pumps must provide sufficient pressure to move the fuel from the tanks) to the carburetor or fuel injector, it is obvious that you should have some way of knowing that the required pressure is being produced.

How Can I Return A Fuel System Part?

As already pointed out, this little matter is taken care of with the installation of a fuel pressure gauge. Many of the small low pressure electric pumps used by builders for carburetor equipped engines do not have internal by-pass valves.

These pumps, when installed to supplement the engine driven pump, must be installed in parallel with the engine pump. Depending on the installation, a parallel system may also require the incorporation of one or more one-way check valves to ensure that the fuel flows only towards the engine and does not escape back to the tank while the electric pump is running.

At any rate, a parallel system will always be more complex than an inline installation (see Figure 2). I know of an instance where the builder was unable to maintain cruise engine power unless his electric boost pump was turned on and running.

A lot of smart folks were stumped by this problem until someone found the obvious - the engine driven pump was the wrong type, and not large enough to feed that fuel injected engine without the help of an auxiliary pump.

Fuel Pump System

Some details about this part: Part Number: C291502-0106 Knob Part Number: S1974-1 If you need additional pictures or have any questions, please let us know. 90-Day Money Back Guarantee: Guaranteed to work and pass your inspection or your money back.

We... When the correct engine driven fuel pump is installed, it will discharge (pump) more fuel than your engine needs. . . actually the pump should be capable of providing a minimum fuel flow of 125% of that required for maximum take-off power.

This excess capacity will not be a problem in the operation of your engine as an internal relief valve-factory adjusted to deliver the fuel at the correct pressure for a particular carburetor or fuel injector installation - prevents the development of excessive fuel pressure at the fuel inlet

. Airplane parts for sale from BAS Part Sales can be shipped to nearly any address worldwide, although there are some restrictions on certain products. All duties and taxes are the buyers' responsibility, so please check with your local customs office regarding these charges.

Some Final Words

We will not mark our aviation parts below value or as "gifts," as it is strictly prohibited under U.S. and international regulations. Instead, installation could be done by deflating the tank and folding or rolling it to its minimum expression, placing the bladder through a check hole, and unfolding it in the desired place.

During installation, the personnel must guarantee there are no wrinkles to avoid contamination from entering the tank. Finally, the fuel reaches the heart of the fuel pump system - the engine driven pump. This mechanical engine driven pump is bolted directly to an accessory pad on the engine crankcase from whence it delivers the fuel under pressure to the fuel injector or carburetor.

A bladder tank is similar to a rigid tank except for being produced in reinforced flexible materials such as synthetic rubber. So, unlike rigid tanks, it does not require large cuts into aircraft structures for installation.

As the temperature in the tank changes, the density and hence volume of the fuel will also change. Therefore, a vented tank is a good idea because it allows fuel to escape if expansion has occurred at elevated temperatures.

S- Fso S- Cessna S Fuel Lever Sender Assembly Lh

© 2023 BAS Parts Sales All rights reserved. | Sitemap Some details about this part: Part Number: 0750624-12 Use Part Number: 0750624-22 If you need additional pictures or have any questions, please let us know. 90-Day Money Back Guarantee: Guaranteed to work and pass your inspection or your money back.

We... There is a bit more on the AC engine pump thing. The later model pumps have been given new Lycoming and AC numbers that supersede the old style pump numbers. . . but that's not all.

Not many moons ago, the AC folks decided to cancel production of their fuel pump repair kits because too many fuel pumps were being improperly repaired. They figured that the cost difference between the repair of an old pump and the installment of a new one was not worth the problems being encountered.

So, forget about overhauling your old AC type engine driven fuel pump. Just keep this in mind. A failed engine driven fuel pump can create a serious fire hazard if the diaphragm ruptures and if the vent has not been connected to a line routed away from the hot exhaust pipes to a safe overboard location.

Sa Alt S- Cessna S Fuel Drain Valve Set Of

Furthermore, the engine won't run any more. . . not without the help of a back-up fuel pump. Some details about this part: Part Number: 1616030-1 If you need additional pictures or have any questions, please let us know.

90-Day Money Back Guarantee: Guaranteed to work and pass your inspection or your money back. We have the best guarantee in... Engine driven fuel pumps have achieved a remarkable reliability record, but they do fail. Most commonly, the diaphragm ruptures and fuel comes squirting out of the drain line.

Such a failure, if it does happen, is, I believe, most often the result of age and not due to a material deficiency. We know that man's best efforts can never equal nature's simplicity and efficiency.

Therefore, it's not surprising that the seemingly simple solution of adding a fuel pump only partially copes with the problem of delivering fuel to an engine without the help of gravity. Gravity never fails but fuel pumps do.

C- S- Cessna M Fuel Primer Assembly

So, to protect yourself from that eventuality, you will have to add a back-up pump of some sort. This auxiliary fuel pump or boost pump is generally used to start the engines, but it also provides added reliability to fuel systems.

According to regulations, both pumps must be independently capable of supplying the engine at a rate of 125% of the maximum requirement. This fuel tank has no part in the structure of the aircraft, so the structure must support it adequately throughout the entire flight envelope.

Rigid tanks simplify repair and maintenance as tanks can be easily removed from aircraft to be repaired and reinstalled, or replaced by a new one. The gascolator is generally located on the firewall and should be the lowest component in the fuel system.

It is always fitted with a quick drain valve so that the entire fuel system can be drained at that point. The gascolator also provides a convenient means for draining some fuel to check for the presence of water during your preflight inspection.

I Live Outside Of The Us Can Airplane Parts Be Shipped To My Country?

The quick drain should be easily accessible without having to remove any cowling or covers. Some manufacturers, and many builders, too, significantly reduce the heat by enclosing the engine driven fuel pump in an aluminum shroud open at the bottom.

A duct from the rear engine baffle pipes cool air into an opening in that shroud to cool the pump.

airplane fuel system, aircraft fuel system quizlet, jet engine fuel system, aircraft fuel tank maintenance, aircraft fuel lines, experimental aircraft fuel injection, fuel system in aircraft, aircraft fuel system repair